Choosing The Right Materials For Architectural Model Making

Architectural model making works as a vital tool for visualizing and communicating design concepts. Selecting the appropriate materials for these models is essential to accurately represent architectural details, textures, and overall aesthetics. Here’s a guide to choosing the right materials for architectural model making Dubai:

Foam board and cardboard:

Foam board and cardboard are versatile and commonly used materials for architectural models, especially for early concept models or massing studies. Foam board is lightweight, easy to cut, and provides a smooth surface for applying details such as windows and doors. Cardboard offers structural strength and can be layered or sculpted to create complex forms. Both materials are cost-effective and ideal for quick iterations during the design process.

Acrylic and plexiglass:

For more refined models that require transparency or a polished finish, acrylic and plexiglass are excellent choices. These materials can be laser-cut to precise dimensions, allowing for intricate detailing of building facades or interior spaces. Acrylic sheets come in various thicknesses and can be tinted or painted to simulate different materials like glass or metal. Plexiglass, known for its durability and clarity, improves the presentation quality of architectural models.

Wood and MDF (Medium-Density Fiberboard):

Wood and MDF are preferred for creating durable and detailed architectural models, particularly for presentation purposes or client meetings. They offer a solid base for intricate carving, milling, or engraving to replicate complex architectural elements like staircases, furniture, or structural components. Wood finishes also add a natural aesthetic appeal to models, making them suitable for showcasing interior design concepts or landscaping features.

3D printing filaments:

Advancements in 3D printing technology have developed architectural model making by allowing precise fabrication of intricate geometries and custom designs. PLA (Polylactic Acid) and ABS (Acrylonitrile Butadiene Styrene) filaments are commonly used for creating scaled-down architectural elements, such as detailed facades or mechanical components. Specialty filaments like wood-infused PLA or flexible TPU (Thermoplastic Polyurethane) can simulate different textures or functional properties in models.

Model making pastes and resins:

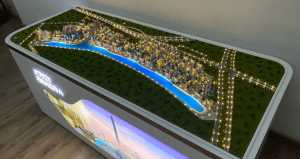

Model making pastes and resins are ideal for achieving realistic textures and finishes in architectural models. Plaster, epoxy resins, or modeling clays can be molded and sculpted to simulate materials like concrete, stone, or vegetation. These materials are invaluable for creating detailed terrain, landscaping features, or interior finishes that improve the realism and tactile quality of architectural presentations.